Engineering & Technology Capabilities

Laser Technology

The use of laser technology in the construction industry is becoming more and more popular, especially among those contractors working on larger-scale commercial projects.

The trend towards laser use is bolstered by the fact that it expedites traditional manual processes, such as leveling, aligning, plumbing and squaring. In addition, laser technology is providing new advantages in areas such as excavation and pipe installation, with the promise of further developments to come.

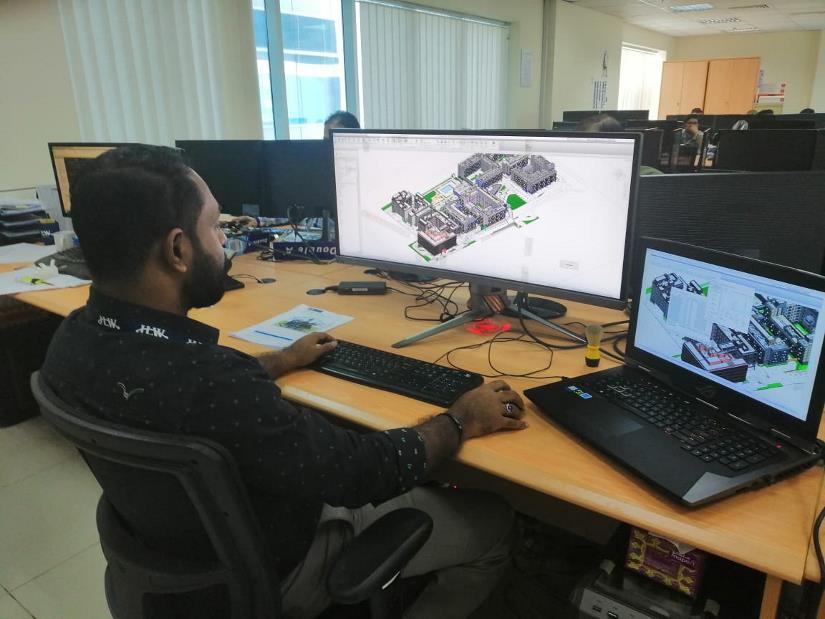

JLW have adopted the use of Trimble’s RTS Robotic Stations and laser setting out technology to locate the exact position of each support point for all our prefabrication modules and major plant and distribution services.

The Process

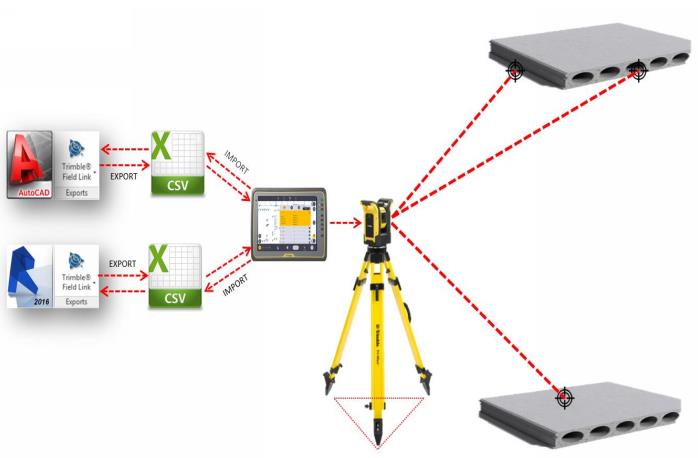

Digital setting out technology basically means transferring BIM models electronically to the Job Site by using a Robotic Total Station and Tablet set up.

This device is then used to locate the drawings specific location points such as hanger points, builders works openings, equipment locations, lighting fixtures and pretty much anything that you can identify in the model.

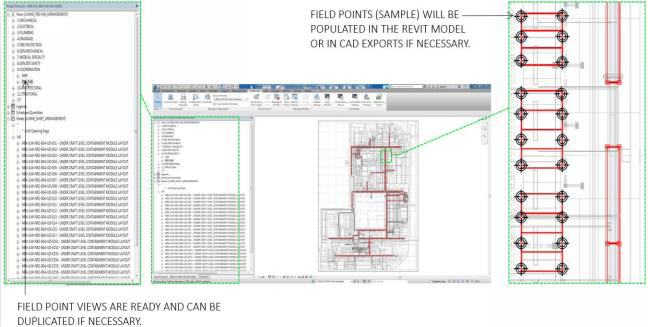

Setting out exact co-ordinates of the support points from the BIM model

Transferring the setout points from our BIM model to the site

In the UAE, M&E contractors get onsite a lot later than their UK or US counterparts. This may be due to the model not having been signed off, the fabrication of systems not being quite on schedule or because of the contractor’s own preference for waiting for all walls to be in because, it’s then easier to manually measure.

More traditional and widespread methods of installations in the UAE is manual marking out either on step ladders or a scissor lift using a number of individuals on a single support point, which we have learnt takes 3 times longer than more using the laser technology.

Since implementing this technology in 2017 we have found the following benefits;

- Digital setting out technology transfers BIM models electronically to the job site, which vastly improved the accuracy of our installations particularly in the use of prefabricated MEP modules.

- 3-5 times as many points can be setout by a single person compared with manual methods (reading plans and using chalk lines and pencils).

- Reduces manpower

- Greater accuracy and reduces mistakes and rework

- Reduces or eliminates the need for field calculations

- Can record changes made at site which can be transferred back to the BIM model for accurate updates on the as built model.