Engineering & Technology Capabilities

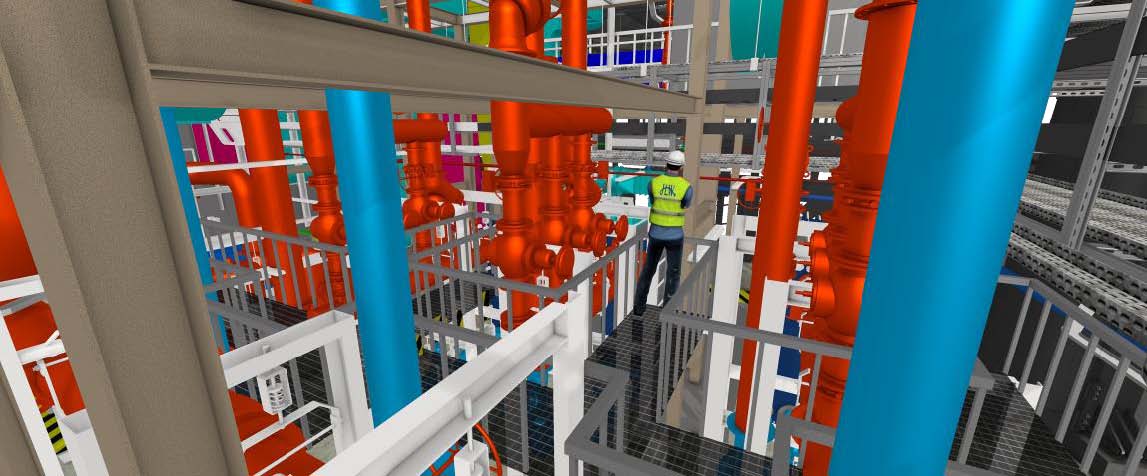

BIM & Digital Construction

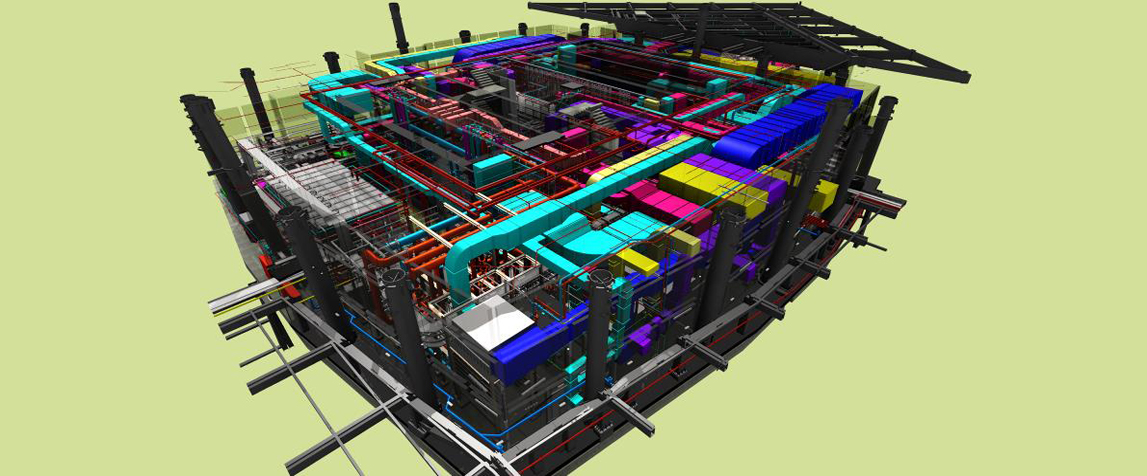

The implementation of Building Information Modelling (BIM) in construction projects involves the digital representation of the physical and functional characteristics of the components that constitute a construction project.

The produced BIM digital model constitutes a reliable basis for decision-making throughout the life of the project and features not only great benefits associated with reduced delivery time, but also, improved co-operation between sectors and lower construction cost of projects.

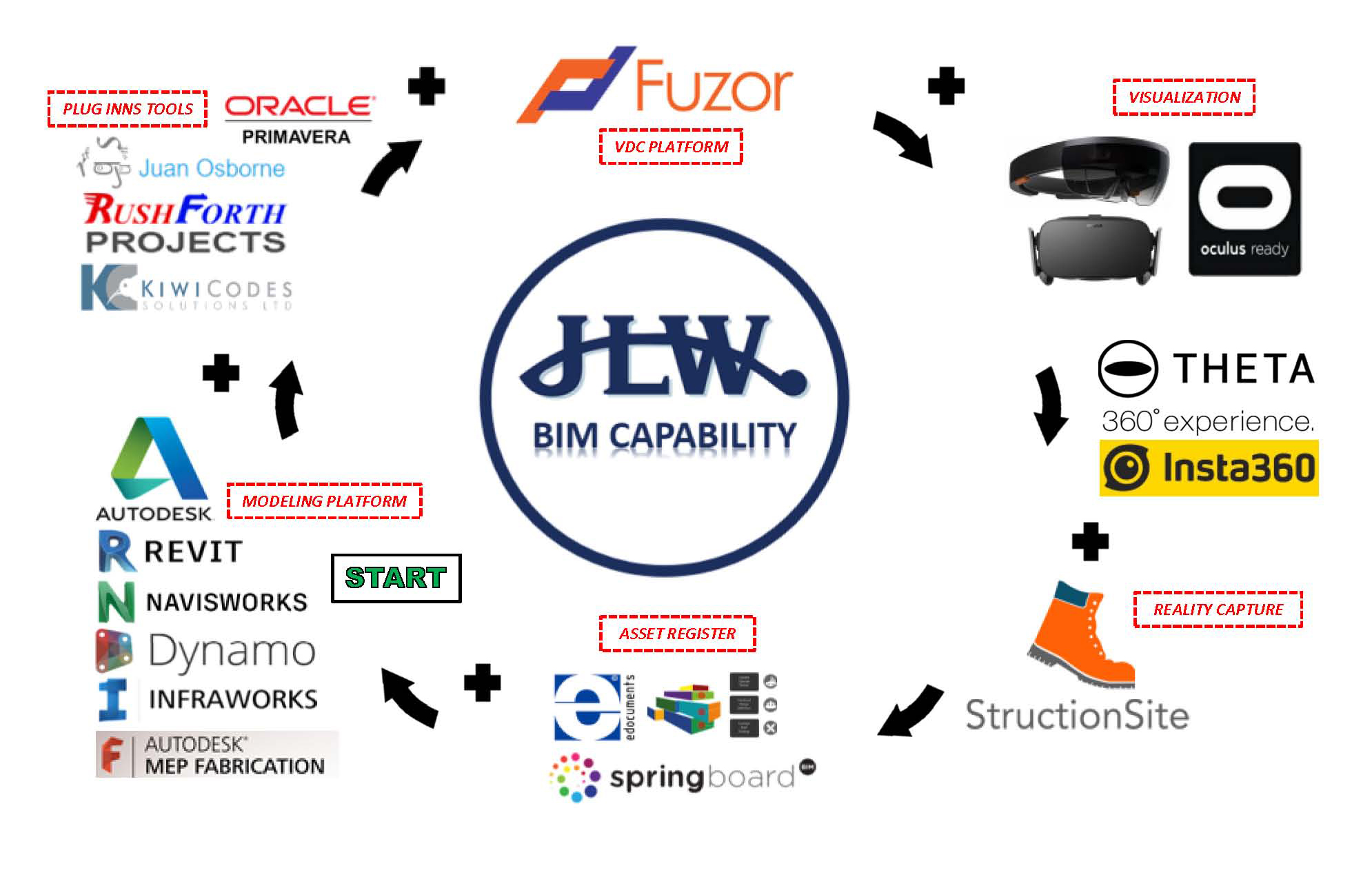

JLW as a business strives in implementing the very latest Digital Construction techniques and aligning this with our internal BIM process with the aim of establishing the following:

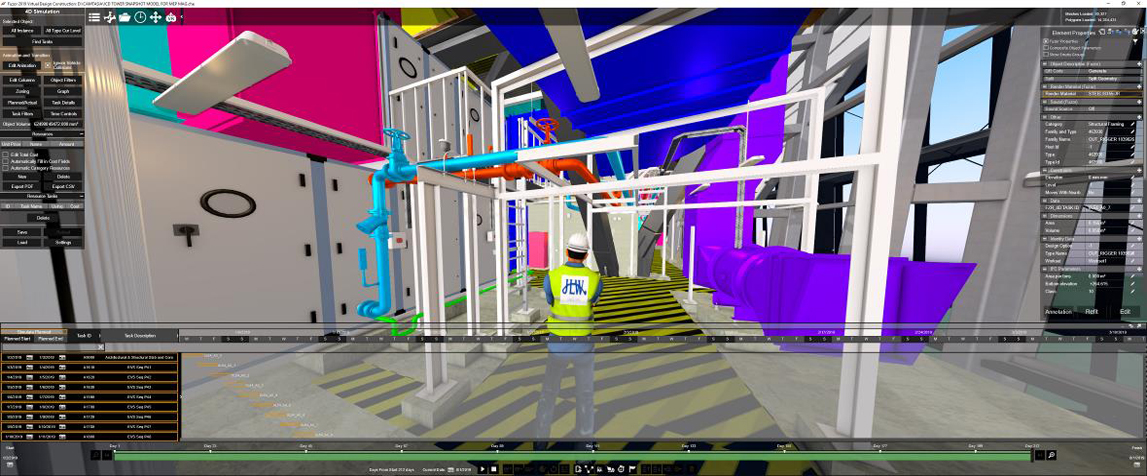

- Adopting VDC software to assist in logistic and construction planning.

- Adopting VR “Virtual reality” and MR “Mixed reality” for immersive digital visualization for collaboration meetings, as well as for actual site conditions.

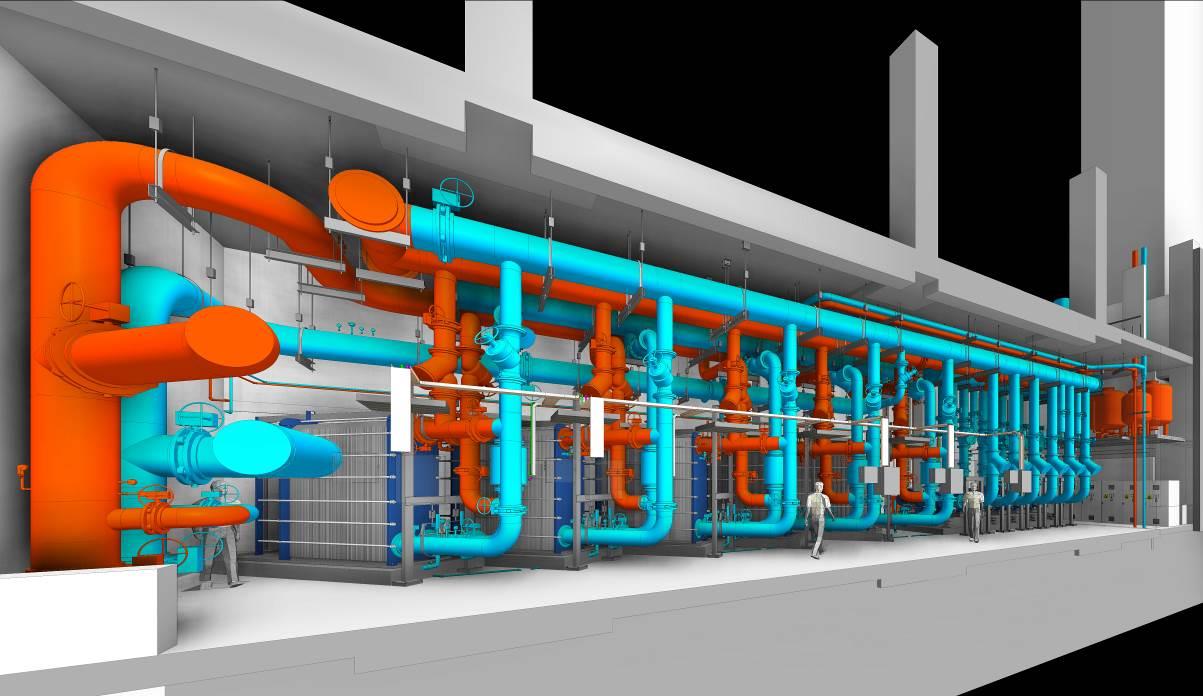

- Enhancing our digital process to increasingly support the use of offsite Pre-Fabrication and MEP modular assembly.

- Using Laser Technology or RTS “Robotic Total Station” along with the process of Pre-Fabricated modules.

- The use of our BIM models for the process of CNC operation precise fabrication.

- Using 4D simulation in complicated and logistically challenging projects or parts of projects to properly plan material procurement and construction sequencing at site.

- Using photogrammetry 360⁰ camera technology for reality capturing of site progress and as built recordings.

- Adopting COBIE in our process to allow our BIM models to be used effectively for facility management once our installations have been handed over.

The Process

This process and digital technology allows us to build our projects once digitally, and then again flawlessly in real life. It really works and so we invite all our partners, clients and subcontractors to join us on the BIM journey right from the start. JLW has invested heavily over the years, and continues to invest in, training our employees in the latest software while investing in software and hardware to make our business more efficient, and to have us stand out above our competitors.

We started our BIM process in 2014. After completing extensive preparations for adaptation to BIM, we became one of the few MEP contracting companies in UAE that implements BIM. For us, BIM is an approach to ensure that the right people get the right information about the project at the right time.

Pre-fabrication is a very exciting topic within the market at present, and we see ourselves as pioneers in this field. Value that pre-fabrication brings to the table is second to none. BIM plays a critical role for us in the success of our prefabrication as it allows us to create very accurate, well-co-ordinated models of our modules before they are constructed offsite in our workshops.

We also utilise BIM during construction to assist our commercial department in anticipating accurate cost to complete by extracting quantities from our Revit Models.

Most recently we have extended our BIM experience into facilities management. We currently offer clients the opportunities to integrate our BIM models and its non-graphical information into facility management software.

Since implementing BIM we have realized the following positive impacts for our business and Clients;

- Cost estimation accuracy within 3%.

- Up to 80% reduction in time taken to generate cost to complete estimates.

- A savings of up to 10-20% of the contract value through MEP Coordination and clash detections. This is achieved through minimising material wastage due to co-ordination clashes, and reduction in labour through the use of off-site prefabrication.

- Up to 15 % reduction in project time, primarily through the use of prefabrication.